Product Description

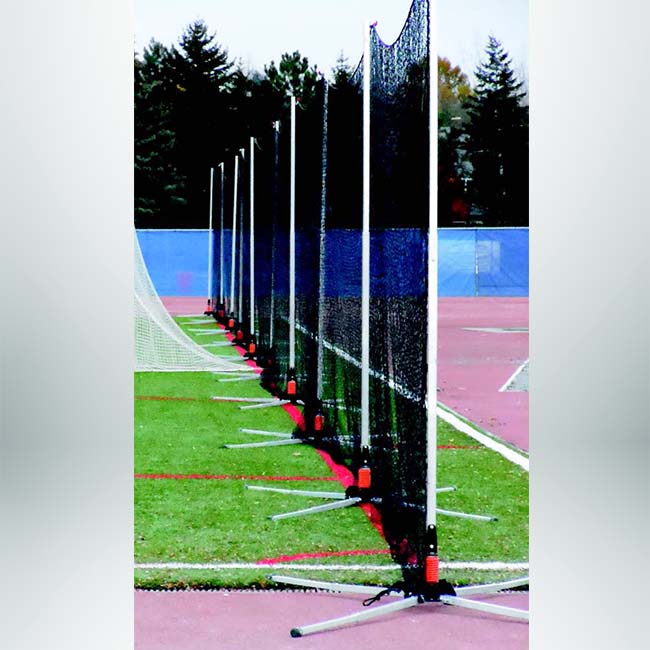

Need to separate your gym into sections for different sports or classes? Walk Draw Gym Divider Curtains can be customized to provide the capability to divide your athletic facility into sections and can be moved easily by one person.

Contact us. We’ll be happy to talk through your options with you.

Advantages of Walk-draw Gym Divider Curtains:

- One person can easily pull the curtain open or shut

- Walk-draw divider curtains can be hung on a track or cables.

- Curtains can be made in various widths and heights and can be custom-designed for your athletic facility.

- Curtains can be made from a variety of materials including Vinyl, Snyder Mesh with Vinyl, or Flex-Mesh with Vinyl, or Vinyl with netting

Wondering if you should get a divider curtain or a divider net? Key differences between divider nets and divider curtains:

- Nets are lighter weight than curtains

- You can see through the nets. You can see through flex-mesh curtains, but not vinyl curtains.

- With a Gym Divider Net a Tension Net System is an option, (it is not an option with curtains.)

- Nets will stretch out of shape over time. Curtains tend to hold their shape better over time.

Learn more about the advantages and disadvantages of different gym dividers by reading our Gym Dividers Buyer’s Guide.

Reviews

There are no reviews yet.